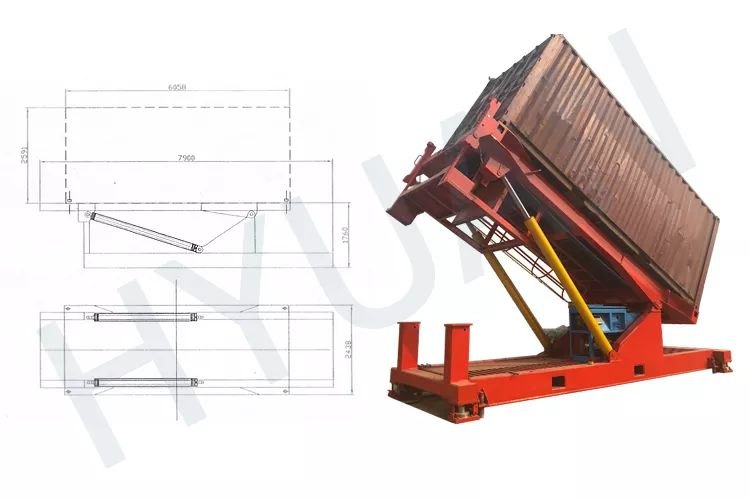

A hydraulic container tilter, also known as a container tilting device or container tipper, is a piece of equipment used in material handling and logistics to tilt or upend shipping containers. These containers are typically large metal boxes used for transporting goods via trucks, trains, or ships. The hydraulic container tilter is designed to assist in the loading and unloading of these containers, making it easier to handle and access the contents.

Key features and functions of a hydraulic container tilter may include:

Hydraulic System: The tilter is equipped with a hydraulic system that provides the force needed to tilt the container. This hydraulic mechanism allows for controlled and smooth tilting movements.

Tilting Angle Control: The equipment usually allows operators to control the angle at which the container is tilted. This feature is important for ensuring that the contents are unloaded or loaded in a controlled manner.

Safety Features: To ensure safety during operation, hydraulic container tilters often come with safety features such as locking mechanisms to secure the container during tilting and emergency stop controls.

Adaptability: Container tilters are designed to handle different sizes and types of containers. They may have adjustable features to accommodate various container dimensions.

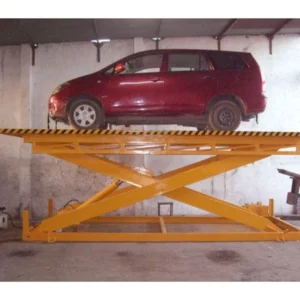

Mobility: Some container tilters are designed to be mobile, allowing them to be easily moved to different locations within a facility as needed.

The primary purpose of a hydraulic container tilter is to improve efficiency in material handling operations. By tilting the container, it becomes easier to access and unload the contents, especially in situations where gravity can assist in the process. This can be particularly useful in industries such as shipping, warehousing, and manufacturing where the handling of large and heavy containers is a common task.